Wood Stove Particulate Sampling Comparison Testing

Brookhaven National Laboratory

December 16 - 17, 2013

Brookhaven

National Laboratory is a multipurpose research institution funded

primarily by the U.S. Department of Energy's Office of Science.

It was established in 1947 at the former U.S. Army's Camp Upton, with a 5,000 acre site near Upton, on Long Island NY.

The arrow shows the testing location, at one of the combustion laboratories of the Energy Efficiency and Conservation Division.

The Director is Dr. Tom Butcher, who is Head of the Energy Resources Division, and was one of the judges at the Wood Stove Decathlon.

Across the street is the National Synchrotron Light Source II, a new $912,000,000.00 facility.

The combustion lab is in one of the original older buildings.

Note the red arrow, which is pointing to a boiler stored in the shed.

One of the wood fired boilers that has been used for testing.

Chimneys.

The black line shows the original footprint in the center of the lab for a chimney that was used for nuclear

work.

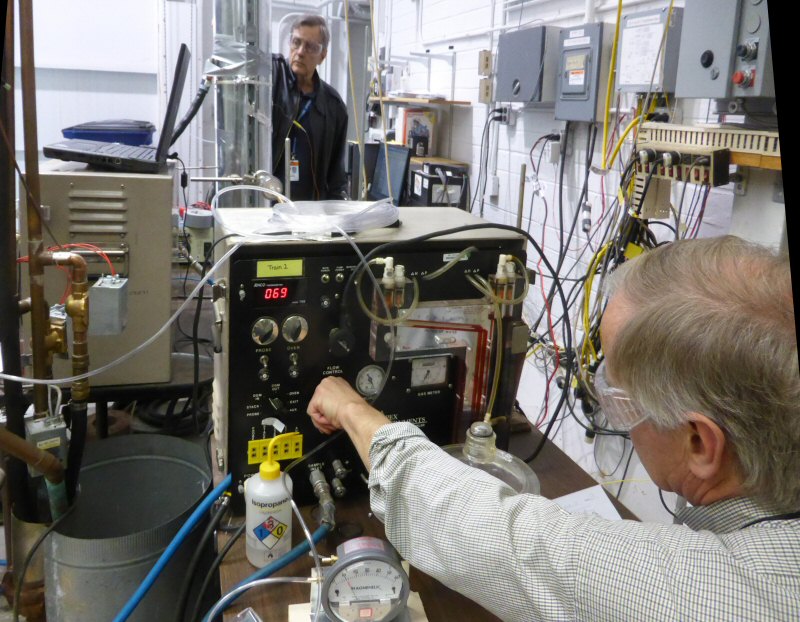

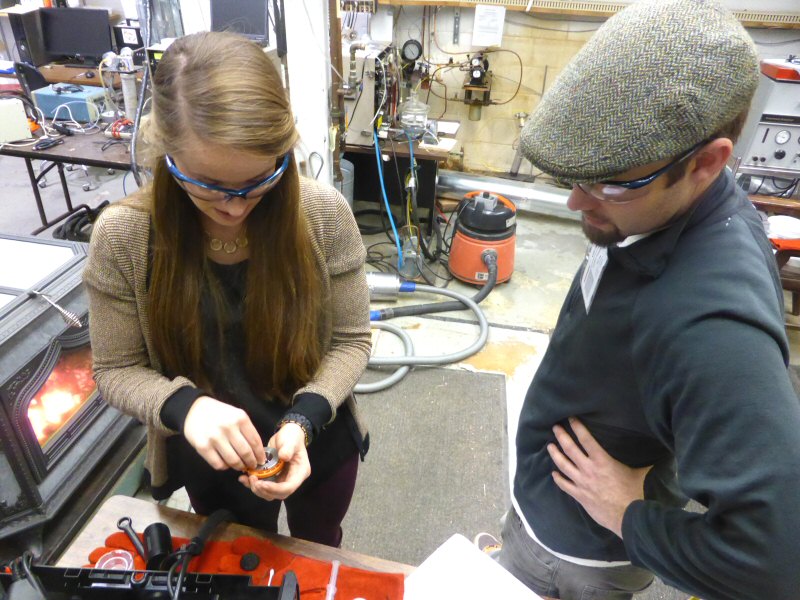

BNL technician Rebecca Trojanowski (centre) monitors one of the two EPA Method 5G sampling trains. She has a master's degree in

mechanical engineering, and was the lead technician at the Wood Stove Decathlon.

Tom Butcher is monitoring the second train. Carsten Homsted monitors the flow in the Condar portable sampler and

adjusts the vacuum motor to keep the flow constant.

Detaching the probe from the M5G filter holder.

There

is a main filter (in the stainless holder) and a backup filter. The

catch remaining in the probe is weighed, and apportioned between

the two filters.

Glass filter with the particulate sample. The filter is weighed on an analytical balance to determine the PM catch.

The same balance was used to weigh both the M5G and Condar filters.

Dessication jar to ensure that the M5G glass filters stay dry. Dessication is a requirement of Method 5G.

In

prior testing, MHA determined that the 6" glass filters used for

the Condar method are not significantly affected by dessication,

and we do not use dessication. We do keep a blank filter that is

weighed along with every run before and after, to flag any moisture

pickup or issues with the scale.

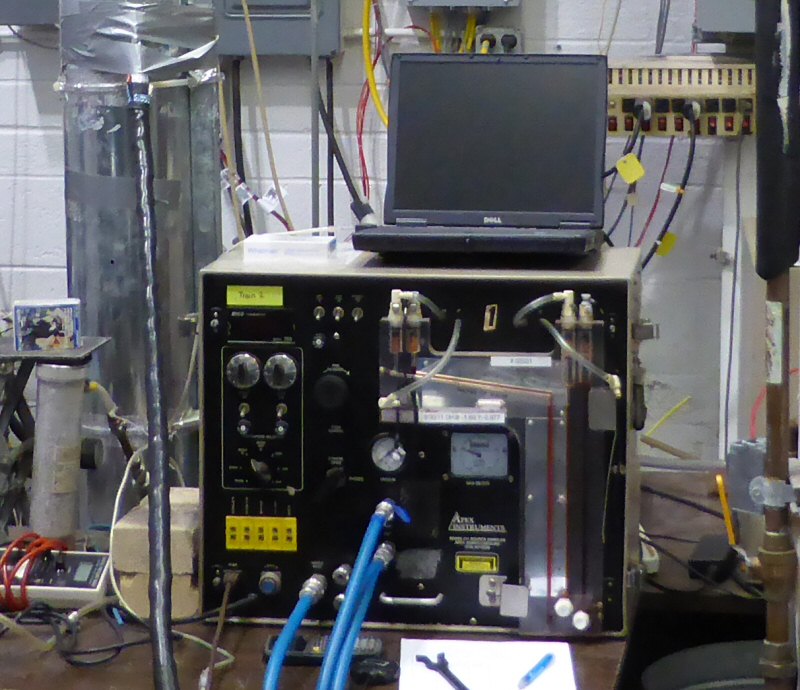

Apex Instruments gas sampling console.

The

console regulates the flow through the filter train with very high

precision. The M5G method uses proportional sampling, where the

sample

train flow is a known fraction of the tunnel flow. The CO ratio between

the stack and the dilution tunnel give the dilution ratio

of the tunnel.

The

Condar portable dilution tunnel is different. The dilution is a fixed

ratio (10:1) and the sample flow is constant, instead of proportional.

This introduces an

error compared to proportional sampling. However, for a cold start batch burning appliances such as a masonry heater, any error

would be to overestimate, since particulates are higher during startup, whereas stack flow is lower than the overall average.

The Condar was used successfully to do a field study of pellet stoves in New Zealand in 2006.

As part of the New Zealand pellet study, the Condar was compared against the Australian/New Zealand laboratory dilution tunnel

method, AS/NZS 4012/3. The correlation was very good, as shown in the graph below:

Gas analyzers. Top left is a paramagnetic O2 analyzer and below that is an infrared CO analyzer. Tom Butcher performs the

calibration, which is done daily.

Calibration

gases. Normally there is zero gas and span gas. Span is the upper limit

of the instrument's range. For very critical work,

you can also use a third calibration point in between zero and span.

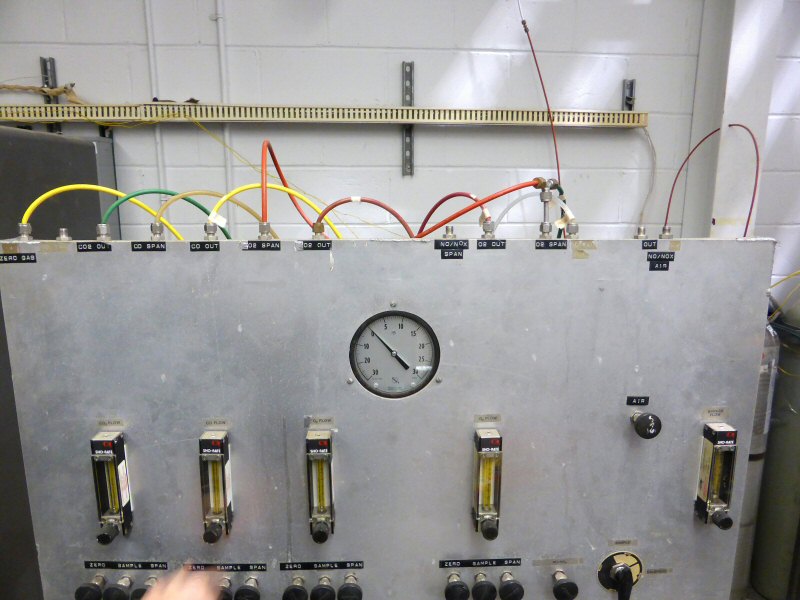

Calibration gas control panel.

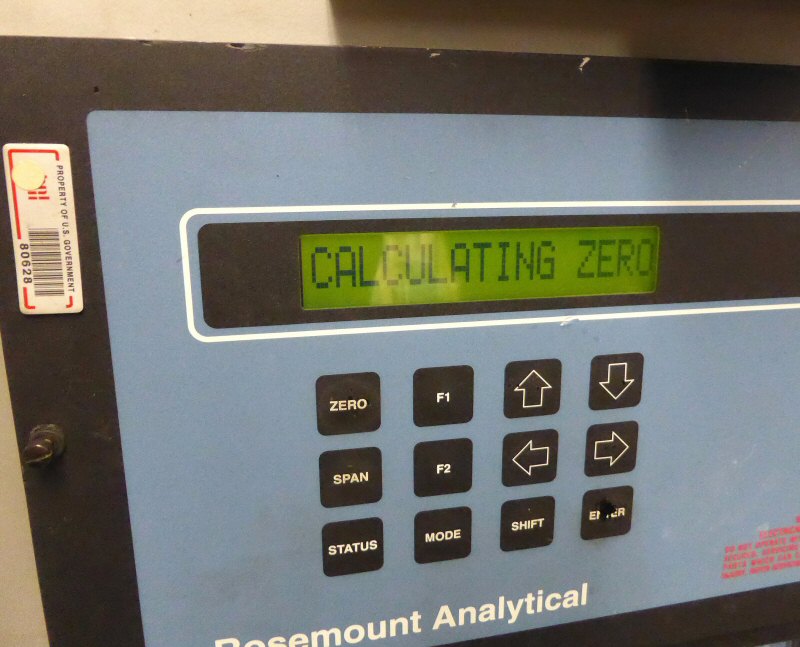

The

CO analyzer performs an automated routine. When you change calibration

gas cylinders, you have to input the specific value on

the new cylinder. The span gas on this analyzer was around 8,000 ppm.

Reading

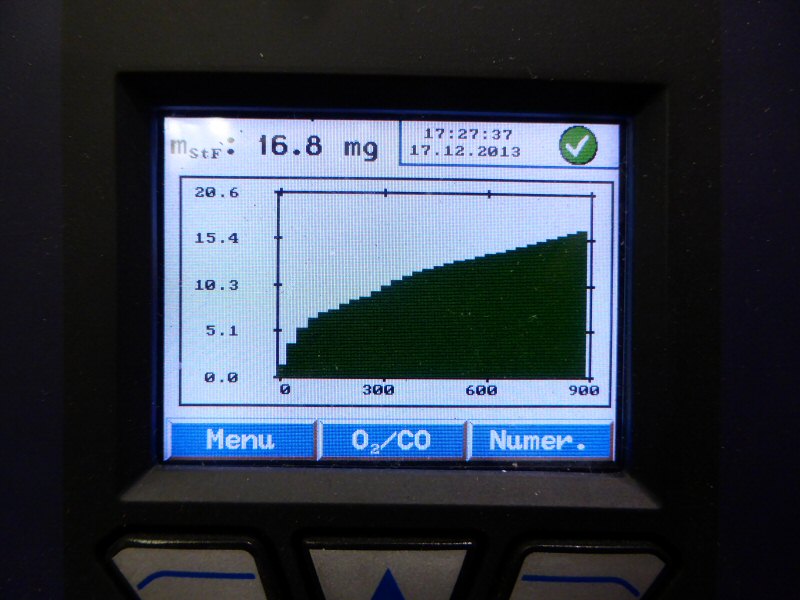

the Woehler analyzer. This is a new German PM sampling system that can

weigh a filter cartridge in real time as it loads up.

It is designed

for the new mandatory German in-home test. It takes a 15 minute sample

and uses "manufacturer's instructions" for firing

the appliance.

Not

surprisingly, "manufacturer's instructions" more or less state :

"establish clean burning conditions and then run the 15 minute test".

This was one of two new German instruments used for field sampling at the Wood Stove Decathlon.

More details on the Woehler.

This graph shows the cumulative filter loading over the 900 second test cycle.

A

dirty run will load the filter pretty quickly. The Woehler is not

designed to measure dirty stoves. If your stove were to get the filter

this dirty, the new German regulation would require the removal of your stove.

Rear of the filter.

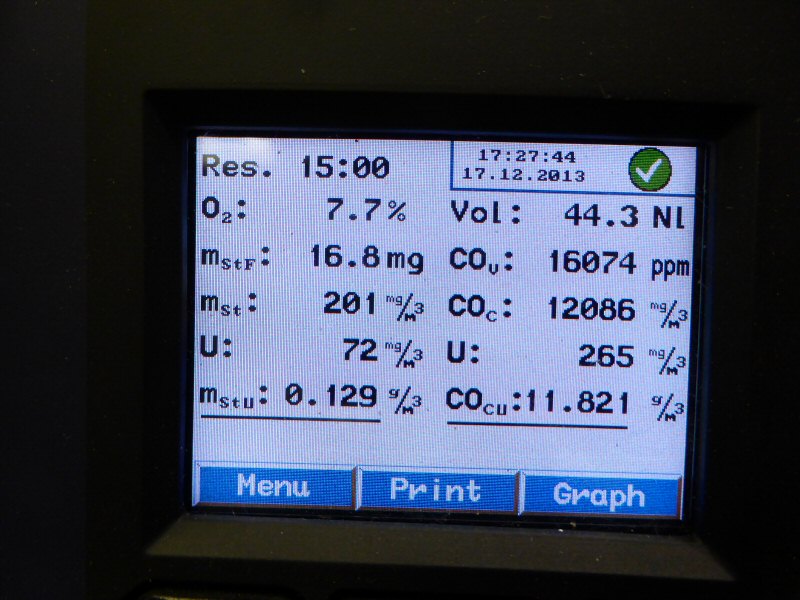

Final readings for the second test run. We did a total of 3 runs over 2 days.

"mst"

at 201 is "Masse Staub" or particulate mass (per standard volume). The

measured particulate emission factor on this run is 201 mg/m3.

This

is adjusted with an "uncertainty factor", so that the reported value

becomes 129 mg/m3. The new German regulation gives you the benefit

of

the measurement uncertainty because if you fail the test, you have to remove your stove.

The

law requires your sweep to test your stove for emissions every two

years. The procedure is part of your mandatory chimney cleaning.

The whole thing takes about an hour and costs $150.00

Rebecca

Trojanowski demonstrates the new Testo 380 portable emissions analyzer.

It is similar to the Woehler, but uses a different

sampling

method. It uses an impactor rather than a filter, also weighed in real

time. We used a Testo at the Decathlon, alternating

runs with the

Woehler. The main reason for the testing project shown here is to

compare the two German instruments with each other

and with EPA Method 5G.

MHA

and the masonry heater community are fortunate to have been invited by

Dr. Butcher to include the Condar in the comparison testing.

The impactor plate is easily cleaned with alcohol, so there are no filters to buy.

Load of fuel ready to go.

Video: loading the stove.

Instruments

were late getting ready for the first burn, so the air was shut down to

prolong the fire. Wood batch was starting to enter

the charcoal phase, and produced this interesting flame sheet, somewhat like a northern lights display (see video below).

Video

Towards the end, looking up, you can see the inlet to the catalytic converter.

Installing

the Condar sampler. The nozzle at the right is inserted into the stack

at 8' above floor level. The plastic hose is connected

to a pressure

tap on the nozzle, that allows the flow rate to be kept constant by

adjusting a vacuum motor as the filters load up.

At the rear is a

connection for a vacuum hose to drive the sampler. The filter are

located roughly mid-barrel and the barrel is in two

sections that clip together.

More information on the Condar.

Ready to sample with the Condar. We sampled during the 15 minute German cycle for comparison with the other methods.

We

used additional filters to extend the sampling to a complete burn

cycle. We attempted to get reasonably close to an EPA number,

which is done with a hot-to-hot batch burn with the stove on a scale.

The downpipe from the laboratory dilution tunnel is visible to the right. This is where the M5G probes are inserted.

The

downpipe connects to two powerful fans that exhaust to the outside. At

the other end, 16 ft above the floor, is a collection hood

that

captures the entire effluent from the stove and dilutes it with room

air to simulate what happens in the atmosphere to condense

tar into sub-micron size droplets and create smoke.

The

German analyzers both sample hot, so will miss some of the volatiles

that condense into PM. This should not make much difference

on clean

stoves such as masonry heaters or pellet stoves, but one would expect

less catch than M5G for a dirty stove. One of the purposes

of this testing was to explore this issue..

Zeroing

the magnehelic micromanometer. The Condar nozzle is calibrated to

provide 0.4 cfm of flow at -12 pascals pressure at the

nozzle..

Carsten Homsted watches the magnehelic as Rebecca Trojanowski keeps an eye on the M5G train.

A speed control is mounted on top of the vaccuum motor to allow adjustable suction.

The Condar uses 6" glass filters, which are kept in the plastic containers behind the magnehelic.

Thanks again to Dr. Butcher and Brookhaven for inviting us to participate in this exciting research.

This page was updated on January 26, 2014

This page was created on December 20, 2013